Stakeholder Decision-Making in the Heart of Hierarchy

"Nothing about us without us!" is a rallying cry, a catch-phrase with a clear moral imperative: that those impacted by a decision should be involved in making the decision.

This approach, stakeholder decision-making, has practical as well as moral benefits. It is highly adaptable, as stakeholders tend to have the best knowledge of the specific situation and how it’s changing. It can also be a quicker process, if stakeholders are empowered to take action.

The slogan "Nothing about us without us" was popularized by disability activists in the 1990s, and tends to be associated with progressive and social justice causes. But stakeholder decision-making has been adopted by some of the most hierarchical organizations in the world, including for-profit corporations and militaries.

In their paper Management Practices, Relational Contracts and the Decline of General Motors, Susan Helper and Rebecca Henderson outline how Toyota and other Japanese automakers out-competed General Motors and other American counterparts. They credit Toyota's success to the use of "relational contracts": a way of dealing with employees, suppliers, and other parties based on delegation of responsibility, respect for context and local expertise, and a willingness to invest in relationships—all key elements of stakeholder decision-making.

Relational contracts, Helper and Henderson write, are "agreements based on subjective measures of performance that could neither be fully specified beforehand nor verified after the fact." Instead of micromanaging relationships, Toyota adopted a position of trust toward both employees and suppliers.

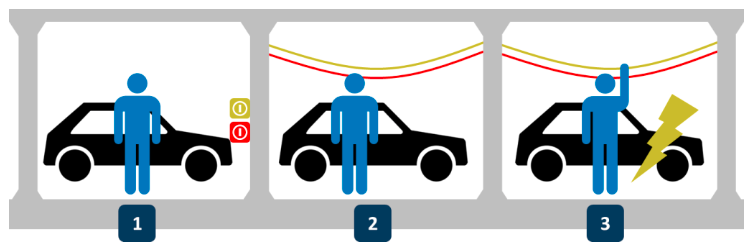

In the case of employees, this involved making workers responsible for assessing the quality of their own work, and asking them to solve problems as they arose. The adoption of the "andon cord" is emblematic of this approach. Workers along the assembly line were given cords which they could pull to halt production. The benefits of this are obvious: workers are ideally positioned to see when something's going wrong. They can quickly flag problems and, depending on the problem, address them.

But halting production is expensive. "Shutting down the line for a popular model could cost $10,000 in lost profits per minute, so management setting up this system needed to be confident that a worker deciding to pull the andon cord would have both the knowledge and the incentive to exercise sophisticated judgment," write Helper and Henderson. Toyota addressed this need by training workers extensively in techniques like statistical process control and experimental design and by involving them in the co-creation of the production process.

This approach was driven by a belief in "genchi gembutsu", translated as "the situation onsite" or "go and see." Helper and Henderson describe it as "the belief [...] that detail knowledge of context is valuable."

Respect for genchi gembutsu also characterized Toyota's relationship with its suppliers. Instead of precisely specifying what they wanted their suppliers to do, Toyota gave them exterior dimensions and performance characteristics and let suppliers use their own expertise to design and create the part. Toyota stayed involved in the process, but their approach was collaborative and focused on knowledge-sharing between their own engineers and those of their suppliers.

Conversely, General Motors relied on short-term, precisely defined contracts with their suppliers. This made it tremendously difficult to do design updates, as changes to designs meant changes to contracts, which would incur large fees. Even badly needed design updates often didn't happen. Meanwhile, Toyota's relationship-based contracts with their suppliers and strong communication made it easy to update designs.

Toyota's genchi gembutsu approach to auto-making echoes the "auftragstaktik" approach to warfare of the German army. Auftragstaktik translates to "mission tactics." In a military that has adopted this style, commanders give subordinates a mission goal but leave it up to them how to achieve it. Auftragstaktik has been part of the German approach since before there was even a Germany; Donald E. Vandergriff, a US Army and Marine veteran, traces the history of the term back to the 1850s.

As with genchi gembutsu, auftragstaktik is based on respect for the importance of local knowledge. Vandergriff quotes Captain Adolf von Schell, a German officer who translated auftragstaktik for the Americans he was visiting: "In the German Army we use what we term ‘mission tactics’; orders are not written out in the minutest detail, a mission is merely given to a commander. How it shall be carried out is his problem. This is done because the commander on the ground is the only one who can correctly judge existing conditions and take proper action if a change occurs in the situation.”

And, just as Toyota invested in its workers so that they could be trusted with the ability to halt production, the Prussian/German army invested in its officers, so they could be trusted with command in the field. "In the German Kadettenschulen (cadet schools) hazing was squelched in a short time. [...] An officer had to be taught self-confidence, independent thinking and responsibility and not to be denigrated," writes Thomas E. Ricks.

Vandergriff agrees: "The core of the success of Auftragstaktik was the strenuous selection and development of German leaders. There were three personal qualities the Germans clearly valued in their officers: knowledge, independence, and the joy of taking responsibility."

The pay-off for this investment was an officer corps that could respond immediately to challenges and obstacles in the field, rather than waiting for orders. The auftragstaktik approach helped make the German army one of the most powerful and successful in the period before and during the two World Wars.

At this point, you may be protesting: but the German army fought under Hitler! And maybe also: corporations foster wealth inequality and corruption! Or: car companies contribute to climate change! Should we be giving them any credit at all?

I would argue that we should—or rather, we should take credit back.

Often the success of our ideological enemies is attributed to that which makes them different than us. 'Sure, the Nazis were evil,' someone might say, 'but their fascist hierarchy sure made their army strong!` And 'capitalism might screw over poor people, but capitalists just know better than the average worker what needs to be done!'

But this is the opposite of what the evidence tells us. Toyota out-competed General Motors because they trusted and empowered their workers and collaborated with their suppliers. The German Army was so effective because they trained their officers to think independently rather than mindlessly following orders. In the later years of WWII, Hitler tried, mostly unsuccessfully, to wrest control over military operations back from his subordinates. Some believe that if he had stamped out auftragstaktik, Germany would have lost more quickly.

The reliance of military and corporate powerhouses on stakeholder decision-making is validating for those of us who champion the approach, but it also gives us reason to be wary. If Nazi Germany can take advantage of this methodology to pursue a nightmare vision of racial purity, then simply adopting the method isn't enough. It must be part of an overall culture which respects diversity and values human life. There are no shortcuts to justice.

But we can still celebrate the success of a methodology that has been too-long dismissed as naive and ineffective. The best, most just, most effective human organizations are those which foster independent thought and critical thinking skills and which trust those who know most about a situation to make decisions on it. It's time to recognize the evidence...even when it shows up in the most unexpected places.

Member discussion